Welding Machines

Since 1964 as a pioneer in the industry, we have over 50 years developing Laser Welding Technology.

The coil joining welding machines for steel industry are sold under the TMEIC brand. Originally, Mitsubishi Electric Corporation has started manufacturing back to 1950’s, Tada Electric Co., Ltd. , a wholly owned subsidiary of Mitsubishi Electric Corporation has taken over it since 2001 till now.

Worldwide Field Service

Worldwide Network

Field Engineering

Remote Support

Why TMEIC as Partner

Maintainability

- Genuine spare parts

- Periodical maintenance

- Remote support

Operation

- Flexible layout

- Safety operation

- Full automatic welding

Cost Effective

- Less maintenance

- Full automatic welding

- Less energy consumption

Experience

- Over 50 years

- Over 450 sets

- Wide variety of materials

Technology

- High mechanical accuracy

- Precise positioning control

- Post annealer/Pre-heater

Reliability

- Stable welding

- Weld inspection system

- Long product life

Worldwide Field Service

- Worldwide Network

- 16 Subsidiaries North/South America, Europe China, India, Southeast Asia Middle East, Australia, Turkey

Field Engineering

- Maintenance support

- Supervisory service

Remote Support

- Online technical support with Remote assist tool

Product Features

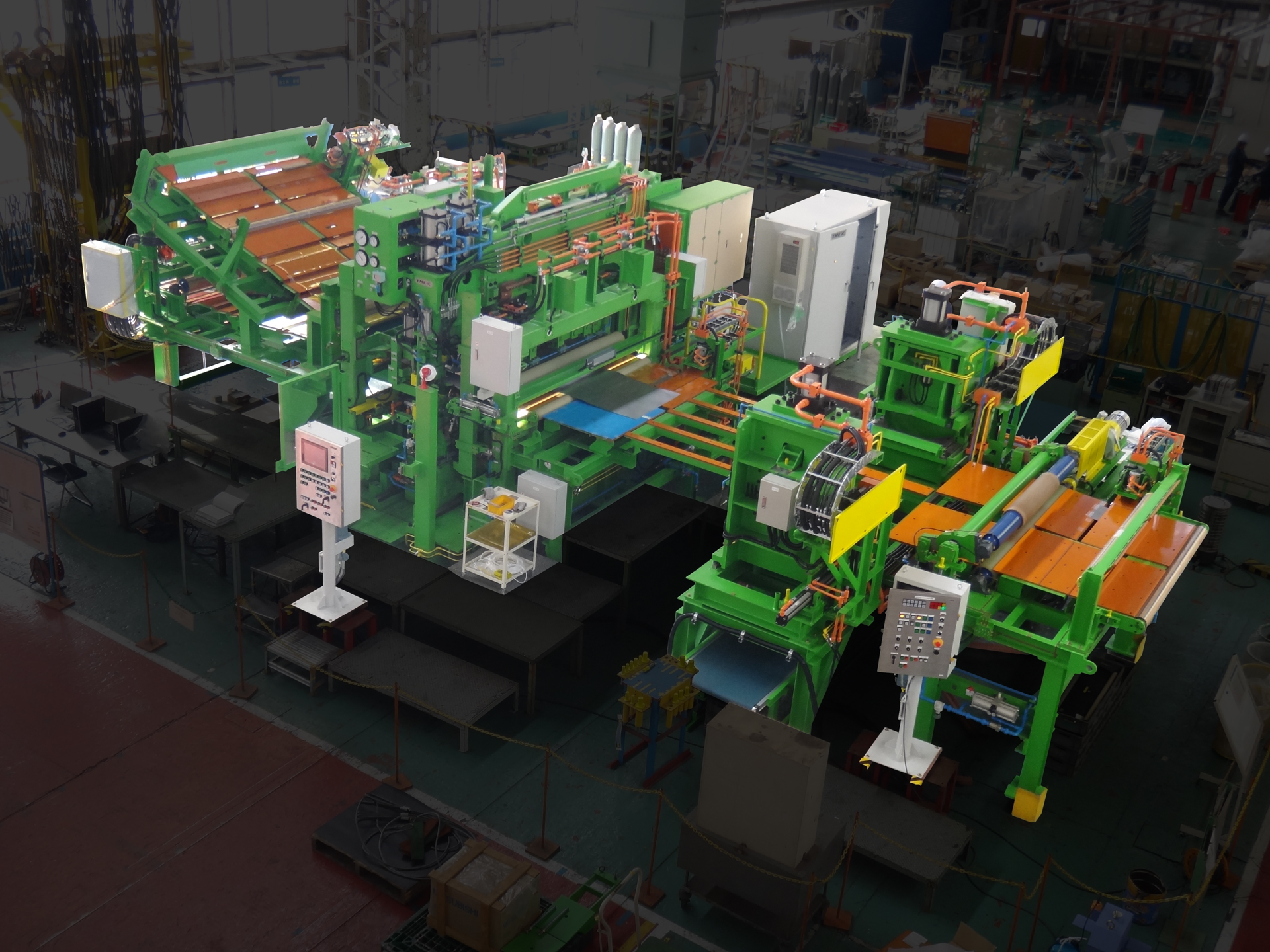

Laser Beam Welder

Laser Beam Welder

|

Mash Seam Welder

Mash Seam Welder

|

|

|---|---|---|

| Thickness |

|

|

| Material | Low carbon steel, HSS, DP, TRIP, Si steel, Stainless steel, etc | Low carbon steel, HSS, DP, TRIP, Si steel, Stainless steel, etc |

| Summary of Delivery Record | Over 50 sets (Asia, Europe, South America, etc.) | Over 290 sets (Asia, Europe, America, South America, etc.) |

| Features | Solid-state laser with high absorptivity rate

TMEIC original Spatter suppressing laser welding head

Automatic Shear clearance setting function

Automatic Bead inspection system

Welding quality judgement system

PLC data and camera image Synchronization monitor

|

Highly Proven Technology for stable welding

Post-annealing system

Monitoring System for stable welding

|

- Thin gauge type : 0.3~3.2 mm

- Standard gauge type : 0.8~6.6(8.8) mm

- Width : 600~2150mm

- Thin gauge type : 0.1~1.0mm

- Middle gauge type : 0.2~2.5mm

- Thick gauge type : 0.3~4.5mm

- Width : 600~2150mm

Solid-state laser with high absorptivity rate

- Deep penetration by high heat input

TMEIC original Spatter suppressing laser welding head

- Realizing high quality product

- Eliminating the effects of spatter on line equipment

Automatic Shear clearance setting function

- Optimum cutting for each thickness

- Making shear blade life time longer

Automatic Bead inspection system

- Assisting operators quality evaluation

Welding quality judgement system

- Effective use of camera monitoring and image processing for quality judgement

PLC data and camera image Synchronization monitor

- Supporting investigation of trouble cause

Highly Proven Technology for stable welding

- High electrode pressure

- Special copper alloy electrode wheel

- Automatic on-line dresser

- Lower electrode height adjustment system

- Brush roll

- Oil dripped welding function

Post-annealing system

- Passing line smoothly for high carbon steel and high tensile steel by decreasing hardness

Monitoring System for stable welding

- Current

- Speed

- Pressure

- Temperature

- Strip lap length before welding

- Welding seam after welding

Request a Quote

Request a Quote

Product request a quote form