TMEIC Develops Synchronous Reluctance Motor Achieving World-Class Continuous Rated Torque

– Contributes to SDGs through high efficiency and eliminating rare earth metals –

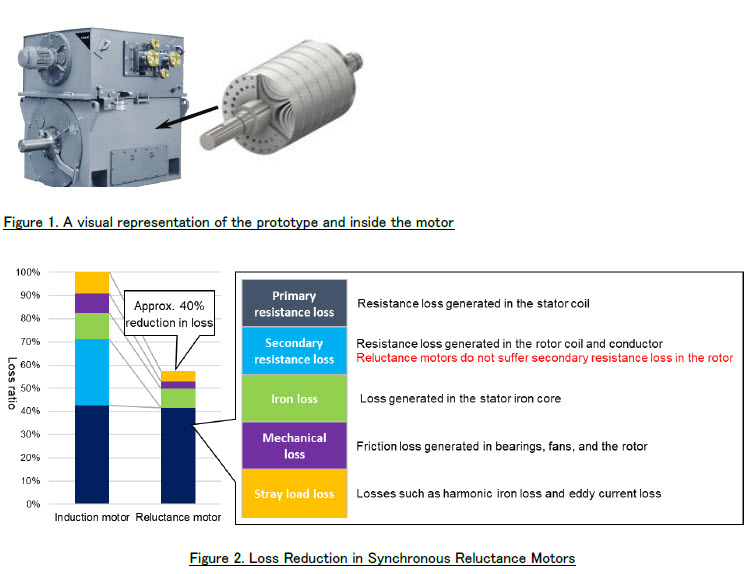

Toshiba Mitsubishi-Electric Industrial Systems Corporation (hereinafter, “TMEIC”; President & CEO Akira Kawaguchi) has developed a synchronous reluctance motor that achieves the world-class*1 rated torque (see Figure 1). The motor applies the technology from the high-efficiency IE5 synchronous reluctance motor, and boasts more than 10 times the continuous rated torque 8.5kNm compared to TMEIC’s conventional lineup. The exceptional efficiency of the motor leads to energy savings in factories and plants while a reduction in resources, including the absence of permanent magnets and rare earth metals, contributes to achieving the United Nations Sustainable Development Goals (SDGs).

Among global efforts towards carbon neutrality, numerous countries have announced their commitment to achieving net-zero CO2 emissions by 2050. Electric motors account for more than 50% of total electricity consumption, and the EU plans to mandate the IE4 energy efficiency level from the current IE3 level for small motors in July 2023. There is also a growing demand for higher efficiency for large-capacity and high-torque motors.

Conventional high-efficiency motors typically use permanent magnets made of rare earth metals. However, these metals are scarce resources whose mining emits large volumes of CO2. This prompted TMEIC to look into developing a motor free of rare earth metals.

The newly developed synchronous reluctance motor boasts higher efficiency and a more space-saving design than TMEIC’s induction motors with loss reduced by 40% and installation space by 20%. This makes it suitable for realizing energy savings in large-scale equipment in factories and plants such as pumps, fans and compressors, as well as a quick return on investment. It is also expected to be applicable to electric propulsion systems for ships with space limitations and weight restrictions.

The features of the new synchronous reluctance motor are as follows.

1. Conserves energy in factories and plants owing to high efficiency, high torque and minimal resources (absence of rare earth metals)

Unlike conventional motors, this synchronous reluctance motor generates torque through the magnetic force exerted on the rotor, which is made solely of steel with no copper or permanent magnets (see Figure 1). Meanwhile, eliminating loss in the rotor enables overall loss to be slashed by around 40% relative to TMEIC’s induction motors, ensuring high-efficiency operation (see Figure 2). As a result, the motor generates less heat, allowing for a more compact design, with a reduction of approximately 20% in the area required for installation compared to our induction motors. In addition, the absence of permanent magnets(rare earth metals) in the rotor, contributes to the SDGs from the perspective of conserving resources.

2.AI technology enables optimal design tailored to individual needs

TMEIC leverages AI technology to determine the rotor shape, which greatly influences the performance of the synchronous reluctance motor*2. This realizes the customized motors with the optimal design that meets specific customer specifications and requirements.

3. Simple maintenance

The synchronous reluctance motor is designed with a simple yet robust structure to ensure advanced reliability. Additionally, since it does not employ permanent magnets to generate magnetic force in the rotor, it does not require specialized equipment for disassembly and maintenance, making these tasks much easier.

Comments by Vice President Hideki Iwanaga, Rotating Machinery Systems Division:

“We have taken the lead in offering a world-class range of high-torque synchronous reluctance motors that can be applied in various fields, including large-scale equipment in factories and plants as well as electric propulsion systems for ships. I expect that TMEIC motors will contribute to energy saving and resource conservation in various fields and promote the wider use of high-efficiency motors.”

TMEIC showcased the newly developed synchronous reluctance motor at the Bari-Ship 2023 maritime exhibition on May 25-27, 2023.

*1 As of April 2023, based on TMEIC research

*2 General Session 5-056 at the 2023 IEEJ National Convention (March 15-17, 2023): “Design Optimization of Synchronous Reluctance Motors via Active Learning Surrogate Model”