TMEIC Supplies Superior Control Systems for Hot Rolling Mills

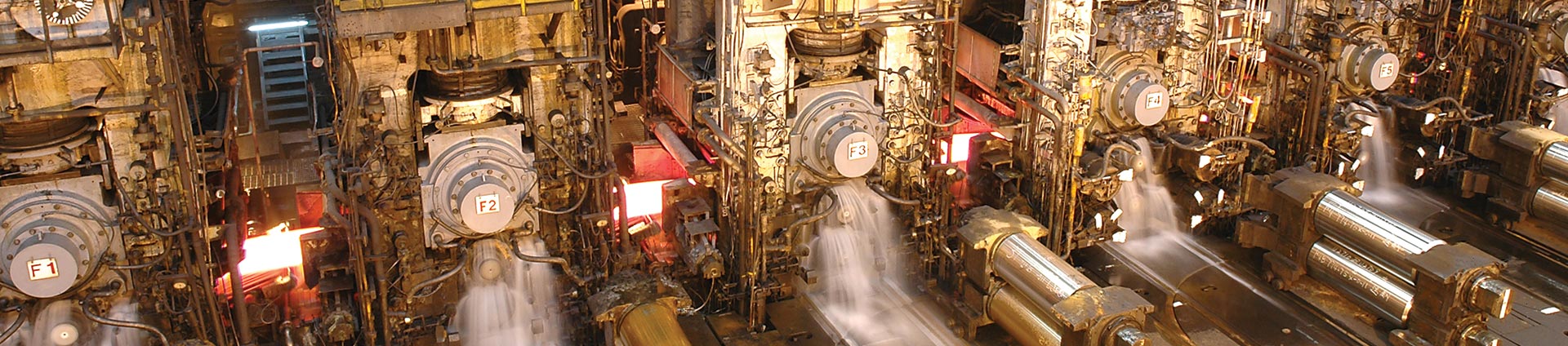

Hot rolling mills roll heated steel, stainless, and aluminum slabs to make hot strip with a thickness of a few millimeters to over ten millimeters. Hot coils are shipped as they are, or moved to another operation and processed to cold rolled sheet, coated steel sheet, or steel pipe. Products are used in various applications such as for automobiles, rail cars, and home appliances.

For these applications, the rolling mill machinery provides high-accuracy control of thickness, width, shape, and process technology for the water cooling to create ductility and strength. TMEIC has a wealth of experience supplying drive systems, automation systems, and process control technology as well as power distribution equipment for hot rolling mills.

Thousands of kilowatts (kW) of power are required to drive roughing and finishing mill stands.

TMEIC configures the power system to provide the most appropriate motors, drives and transformers for the rolling mill. This is done by performing a mechanical torsional vibration analysis of the motor and load, a simulation of the drive speed response, and an electrical power system analysis.

The automated rolling mill data is continuously monitored in the operators’ control room. TMEIC provides ergonomically designed operator desk controls and HMI monitoring systems.