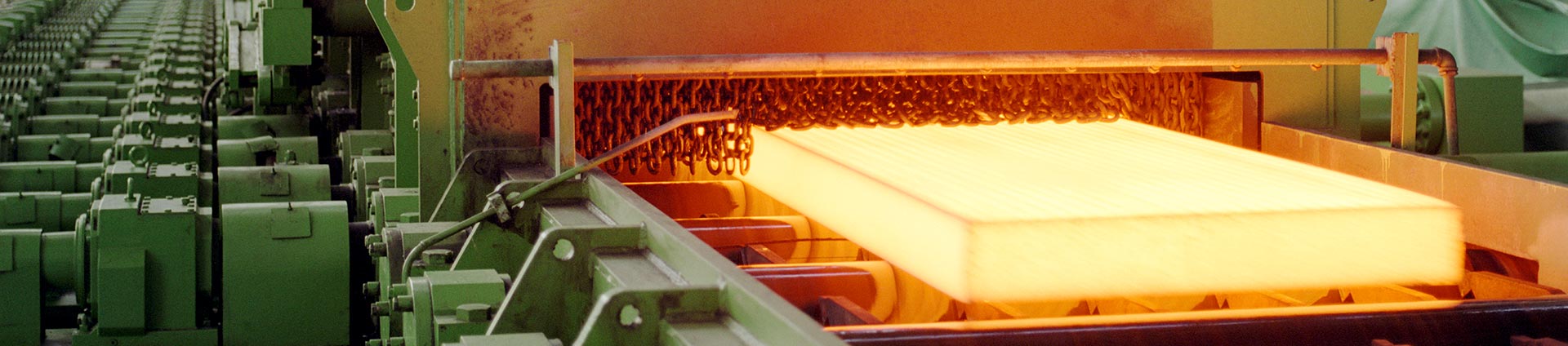

A Plate Mill rolls preheated slabs to produce steel plates with thicknesses from several millimeters to several hundred millimeters.

The steel plates are used for applications such as shipbuilding, bridge construction, civil engineering, industrial machinery, and offshore structures, which require high quality and high strength for reliability. TMEIC provides electric equipment for plate mills including the power-supply system, drive systems, automation, and process technology, all based on extensive mill experience. TMEIC also provides Ultrasonic Testing to insure the high quality and reliability of the steel plate.

Steel plate mill scheme

1. Mill Set Up Calculation; MSUC This function calculates process regulator references and gains for rolling a specific product. It improves the product quality by using sophisticated physics modeling, flexible pass scheduling, and a model learning function.

2. Automatic Width Control (AWC) can be applied at each edger to provide in-bar width control to increase the width accuracy by adjusting the roll gap.

3. Automatic Gauge Control (AGC) is a closed loop control function designed to regulate thickness at the exit of the rolling mill stand to increase the thickness accuracy.

4. Crown and Flatness Control This function is designed to control the crown and flatness to the target level by changing the shift volume and bending force.

5. Temperature Controlled Rolling (TCR) is a special mill setup designed to incorporate time delays. With several steel plates in line at the same time, steel rolling is executed by controlling the temperature (actual or expected) to achieve certain final material properties.

TMEIC achieved TCR with six plates in line, which was the first time this has been done.