TMEIC Develops Self-Circulating Sleeve Bearing Oil Cooler Unit to Reduce Temperatures in Industrial Motor Bearings

– Motors with self-cooling capabilities realizing equipment reduction and space savings –

Toshiba Mitsubishi-Electric Industrial Systems Corporation (hereinafter, "TMEIC"; President & CEO Akira Kawaguchi) has developed a self-circulating sleeve bearing oil cooler unit to reduce the bearing temperatures of industrial motors and has commenced sales for motors configured with self-cooling bearings using this unit. TMEIC offers a product lineup for these motors with self-cooling capabilities, reaching world-class maximum output*1. This facilitates the optimization of facilities and space in factories and plants, contributing to reductions in installation and maintenance costs.

Sleeve bearings, supporting the rotor (rotating component) of large-capacity industrial motors, necessitate additional cooling measures in high ambient temperatures or when using motors with high capacity and speed. In such conditions, bearing temperatures rise, requiring the installation of separate forced lubrication systems and large oil tanks for effective cooling. Particularly in the Middle East region, where the demand for seawater desalination plants is on the rise, the necessity for cooling systems for bearings is crucial due to the high-temperature environment. In this context, the installation of separate cooling facilities involves considerations for initial costs and the allocation of installation space. Consequently, there has been growing demand for self-cooling solutions, eliminating the need for separate cooling facilities.

TMEIC developed a self-circulating sleeve bearing oil cooler unit in response to these needs. This unit, equipped with a pump attached to the motor, circulates lubricating oil between the bearing and the cooler. This allows for the cooling of the motor's bearings without the need for separate facilities.

The features of the newly developed unit are as follows.

1.Expands the motor output range to world-class levels, especially for large-capacity, high-speed, and high-temperature environment applications

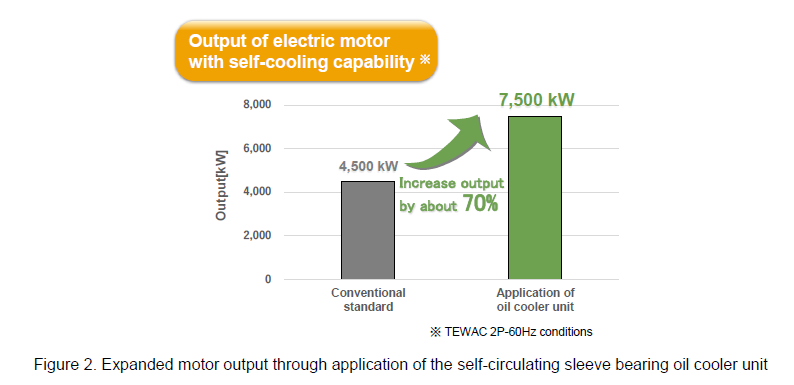

The unit is applicable in environments with ambient temperatures up to 55°C. Using the unit enables significant expansion of the output range of motors capable of operating without a forced lubrication system, reaching a world-class level of 7500 kW (approximately 1.7 times larger than standard models)*2. This enhancement allows for the installation of high-output motors in limited spaces, especially when operating under conditions such as using large-capacity or high-speed machines or in high-temperature environments such as a seawater desalination plant in the Middle East.

2.High maintainability due to simple structure

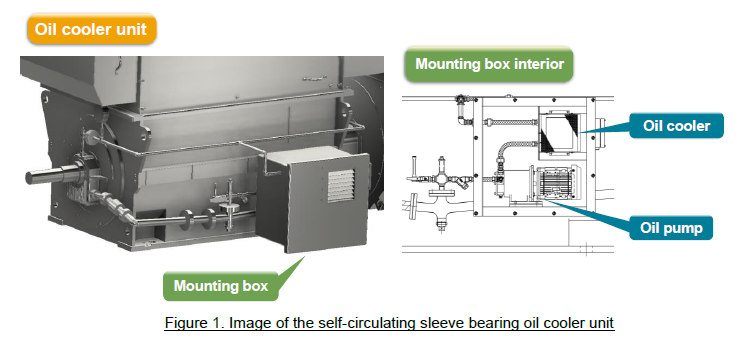

The unit features a simple structure consisting of a mounting box that houses the pump and cooler, along with piping (Figure 1). Flexible tubes are utilized in the piping, allowing for easy detachment of the unit and

contributing to its high maintainability.

3.Can be retrofitted to existing motors

The unit is adaptable for retrofitting to existing motors, offering a solution for scenarios where there is a need to lower the bearing temperature of established motors or to eliminate a force feed lubrication system.

Comments by Vice President Hideki Iwanaga, Rotating Machinery Systems Division:

“Through the development of the self-circulating sleeve bearing oil cooler unit, we have significantly expanded the range of self-cooling bearing specifications. This advancement enables us to offer large-capacity and high-speed machines, addressing the needs of our customers in high-temperature environments as well as those seeking facility and space optimization. TMEIC remains committed to responding to our customers' needs through technological innovation and product development.”

*1 As of August 2023 based on TMEIC research

*2 Under TEWAC (2P-60Hz) conditions with an ambient temperature of 40°C