TMEIC Receives Order of its Busbar Bonding Machine for a New Solar Cell Plant in China

TMEIC Receives Order of Its Busbar Bonding Machine (TMBBM) for a New Solar Cell Plant of Triumph PV Materials Ltd. in China

Toshiba Mitsubishi-Electric Industrial Systems Corporation (hereinafter, “TMEIC”; President & CEO Masahiko Yamawaki) received an order for three units of its Busbar Bonding Machine (TMBBM) for Triumph PV Materials Ltd.*1 The products will be delivered to the world’s largest CIGS*3 plant (300MW in Phase 1 with a production capacity of 1.5GW) constructed by Triumph PV Materials Ltd. in Bengbu City, An Hui Sheng, China.*2 The TMBBM units are scheduled to commence operation in October 2017 and will additionally be installed at a new plant constructed by Triumph PV Materials Ltd. in Jiangyin, Jiangsu, China.

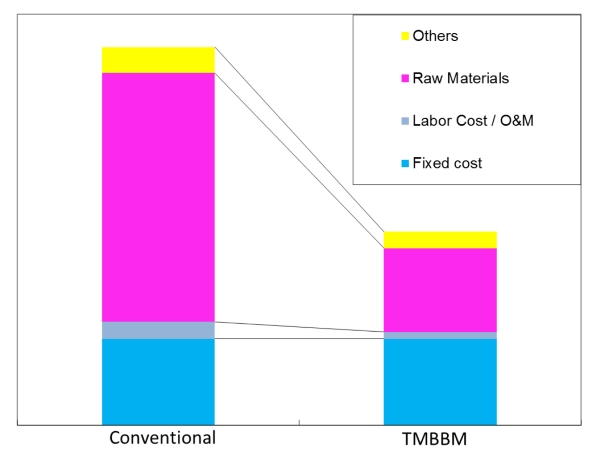

TMBBM applies TMEIC’s proprietary ultrasonic welding technology to directly bond electrodes such as aluminum ribbon to solar cells’ glass substrates. While it has been common to use welding materials such as solder and paste, this machine realizes welding without these materials, thereby reducing the manufacturing cost of solar cells’ wiring process by approximately 50%*4.

TMEIC, together with Mitsubishi Diamond Industrial Co., Ltd. (hereinafter, “MDI”), consistently handles the sequence of processes from patterning to welding electrodes, which in turn ensures the quality of solar cells, improves the yield ratio and builds a sustainable system that will realize vertical start-up at the time of constructing a production line. MDI and TMEIC were selected exclusively as a Japanese supplier for the current project. Going forward, in order to make inroads into other areas such as perovskite-based solar cells*5, for which there are high expectations as next-generation solar cells in addition to CIGS, TMEIC will continue cooperating with MDI to actively make proposals to solar cell manufacturers in respective countries worldwide in an effort to expand sales.

Benefits of Employing TMBBM

- Because there is no need to use welding materials, this will significantly contribute to reducing the manufacturing cost and environmental load.

- Direct welding reduces contact resistance and enhances welding stability.

- The welding process at normal temperatures does not cause heat damage to substrates and the foundation layer.

*1) CIGS thin film solar cell manufacturer under the umbrella of China National Building Materials Group Corporation, which is the world’s largest group handling comprehensive construction materials.

*2) See press release of AVANCIS GmbH, which is a company under the umbrella of China National Building Materials Group Corporation that is responsible for bringing together the technologies of this project. http://www.avancis.de/en/press/news/article/spatenstich-fuer-groesste-cigs-solarmodul-produktion-in-china-avancis-liefert-cigs-technologie-fuer/

*3) A CIGS solar cell is a compound semiconductor-based solar cells made up of copper (Cu), indium (In), gallium (Ga) and selenium (Se). Its production cost is moderate compared with other solar cells such as crystalline silicon solar cells and it has the property of being strongly resistant to heat and shadow.

*4) Production cost reduction effect of solar cell wiring process

*5) Next-generation solar cell with perovskite crystal structure. In addition to high conversion efficiency, it also can be produced at moderate cost compared to current mainstay silicon solar cells.

Media inquiries:

For further information, please contact the Corporate Branding Group at TMEIC.

Tokyo Square Garden, 1-1, Kyobashi 3-chome, Chuo-ku, Tokyo 104-0031, Japan

Tel: +81-3-3277-4319; Fax: +81-3-3277-4578

http://www.tmeic.co.jp/

In order to respond to the needs of manufacturing sites that serve as a foundation for supporting society, TMEIC always sets its eyes on the future of industry, society and the environment as an industrial systems integrator striking a balance between the development of society and a beautiful global environment. TMEIC will contribute to manufacturing and environmental management through leading-edge technologies based on its core technologies of rotating machinery, power electronics and engineering.