AC adjustable speed motor drive systems are the preferred technology for new rolling mill installations and modernization projects.

TMEIC designs and manufactures two types of AC solutions for this purpose.

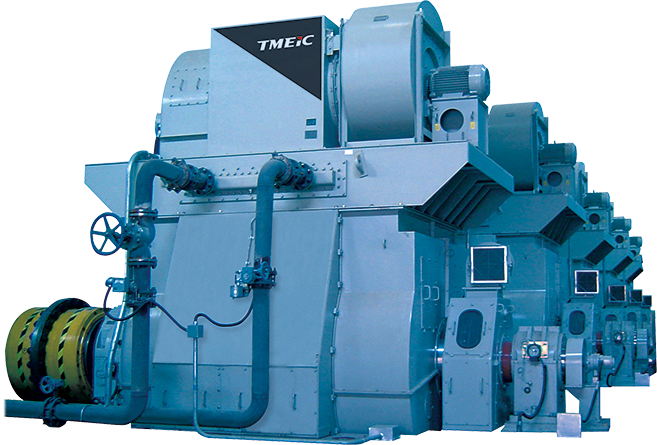

- Salient pole synchronous motors that meet the high power and torque demands of a hot strip mill, as well as roughing and finishing stands.

- Excellent torque characteristics

- Superior efficiency

- Unit power factor

- Easy to control

- Squirrel cage rotor motor applied to medium power requirements of reels and stands.

- Extremely robust construction

- Excellent torque characteristics on ultra-low speed rolling applications

- Constant power output throughout field weakening range

- Meets NEMA MG1 and JEM 1157 standards.

These motors have:

- Superior efficiency

- Robust frame and shaft construction

- Less demand for maintenance

- High degree of control and responsiveness

- Great capacity for acceleration and deceleration.

- Greater flexibility for extreme operating conditions