Predictive maintenance device for electric motors.

- Connected to the IOT

- Easy to install and start up

- Parameter monitoring and failure prediction

More than just a sensor TMAS Smart Motor Sensor (TMSMS) monitors the condition of your electric motors by combining best-in-class sensing technologies with leading-edge data analysis. TMASMS detects anomalies and defects in equipment, enabling you to forecast maintenance cycles and avoid unplanned downtime.

More than just a sensor TMAS Smart Motor Sensor (TMSMS) monitors the condition of your electric motors by combining best-in-class sensing technologies with leading-edge data analysis. TMASMS detects anomalies and defects in equipment, enabling you to forecast maintenance cycles and avoid unplanned downtime.

TMASMS covers the most critical diagnostics, translating data into actionable insights. The Smart Motor Sensor allows for 24/7 condition-based monitoring of all your low voltage electric motors. It presents information in a clear way, telling you both what the problem is and how to fix it.

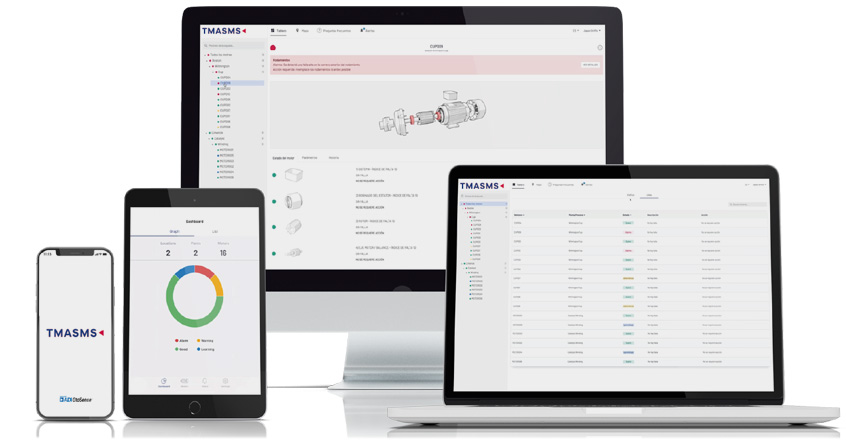

Mobile Application

The TMASMS app allows easy setup of your Smart Motor Sensors, visibility on deployment data, as well as in-app notifications and alerts on critical events.

Dashboard

Get a complete overview of your machine health diagnosis and fault detection with detailed information and visualization of each motor's status.

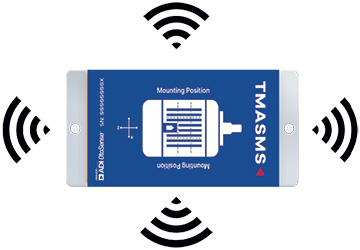

Powerful Motor Smart Sensor

Monitoring - The monitored data is sent via Wi-Fi to the TMASMS operating system, which is an expert in predicting breakdowns.

Software - It analyzes the information, detects faults, and diagnoses, and prescribes appropriate maintenance actions.

Application - Through the TMASMS Motor Sensor App you can access the operation and status of the motor in real-time.

Sensor - Detects parameters and indicators such as temperature, vibrations, and speed, essential for the operation of the motor.

How it works

1. Set up - Configure TMASMS Sensor using the iOS or Android app. Deploy the smart motor sensor within minutes, even while your motor is still running.

2. Learn - Once the sensor is set up on the motor and is commissioned, the learning process has started. Leave sensor running during normal operation.

3. Receive alerts - View your alert in the web dashboard or the mobile app. This allows you to prevent any electrical motor failures.

Benefits

TMASMS optimizes your production environment and reduces breakdowns using robust condition-based monitoring hardware and software. Realize benefits such as lowering asset maintenance costs, extending equipment life, and increasing uptime.

Real-time monitoring

Monitor your equipment more frequently to know when mechanical and electrical failures start to occur and how these issues impact your production process.

Diagnose and take action

A unique model is created for each motor to deliver optimized diagnostics that align with the process. The smart motor sensor provides the information you can use to not only diagnose the problem but know the severity so maintenance teams can take action

Optimize your business

By continuously monitoring your motor performance and health, you will have better visibility into maintenance and spare parts need to know what to order and when to order, reducing inventory costs.

Failure Detection

TMAS Smart Motor Sensor (TMASMS) is the most accurate solution on the market to sense and interpret your machine data. This is why we define ourselves as a sensing interpretation world leader. The SMS can detect the following failures:

- Power System – Asymetry in motor currents

- Stator Winding – Stator resistance variation

- Rotor - Rotor resistance variation

- Motor Shaft/Balance - Gravity center displacement

- Alignment - Motor/load misaligned

- Cooling System - Motor cooling system problem

- Eccentricity - Stator/rotor concentricity issue

- Bearing – Failures/defects in bearing

- Soft/Loose Foot – Fixing system problems

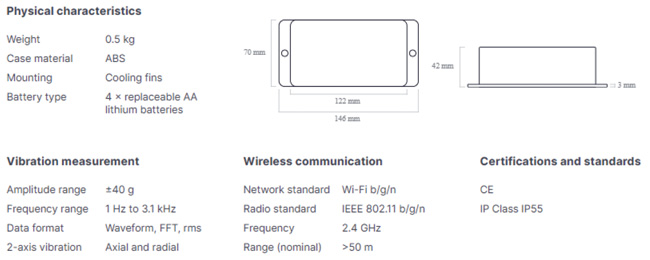

Technical Information

Motor Capability

The Smart Motor Sensor (SMS) works with:

- 3-phase squirrel cage induction motor.

- Standard low voltage IEC and NEMA motors.

- Frames up to 450 (IEC 60034) or 500 (NEMA MG1) whose power range varies from 0.37 kW to 500 kW or from 0.5 hp to 700 hp.

- Motors driven by any type of device (directly online (DOL)), by variable frequency drive (VFD), soft starter, and star-delta.

Specification

Requirements

Network

| Network | Dedicated 2.4GHz network (5GHz networks are not supported) |

| Security | WEP, WPA, or WPA2 |

| Signal strength | Greater than -60dB |

| Ports | Port 8883 and HTTPS port (port 443) must be open. |

Environment

| Operation | -40°C to +60°C |

| Storage | 50°C maximum to avoid energy leakage from lithium batteries |

App

| iPhone | iOS 13 or later |

| iPad | iPadOS 13 or later |

| Android phone/tablet | Android 6.0 (Marshmallow) or later |

Manual and Documentation

TMASMS is a device that performs predictive maintenance on low voltage electric motors. This manual acts as an installation, configuration guide, and web user guide for TMASMS. Read this manual carefully and perform the steps sequenced specified herein.

Documents

FAQ

Can any Wi-Fi modem be used?

Any Wi Wi-Fi modem with 2.4 Ghz connection can be used

Do customer must renew subscription fee?

The subscription fee is annual (one year) basis. After one-year customer must renew the annual subscription fee.

What batteries does TMASMS use?

TMASMS uses 4 AA batteries, recommended battery type is Energizer L91 lithium

What is the maximum motor capacity that TMASMS covers?

At the moment, TMASMS can be used for diagnosing from 0.37 kW to 500 kW. Further research is ongoing so TMASMS can be used for higher capacity motors

Can TMASMS be used for MV or HV motors?

At the moment, TMASMS is designed for LV motors, MV and HV motor used is under research

How do I add a motor, can it be done from the website?

Motor addition can be done only from the mobile app.

What signals data are sent by the TMASMS device to the cloud?

TMASMS sends motor vibration, motor magnetic field, and motor temperature data.

What types of notifications are available and how are they sent to the user of SMS?

Notifications available are:

1. Completion of learning

2. Notification of a motor failure

3. SMS device disconnection

4. Recovery of SMS device communication

5. Low battery level

Can we install TMASMS on a vertical motor that does not have fin?

Yes, TMASMS can be installed on a vertical motor even without fin. Special attachment base for TMASMS need to be ordered separately